PZT-based piezoelectric ceramic

TFT distributes PZT-based piezoelectric ceramic products that are produced by Tayca Corporation, which is our parent company.

We conduct an integrated production approach from raw material powder to the piezoelectric ceramic elements.

We have a wide variety of ceramics with dielectric constants and coercive electric fields.

Various electrode options are available.

Please feel free to contact us with your inquiries and we propose materials that best suit to your request.

Full property sheet for PZT based piezoelectric ceramic

| Item | Symbol |

Material Unit |

L-125 | L-145N | L-155N | L-155NF | L-304 | L-11 | L-201F | L-901 | L-13 | H-8 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Relative permittivity |

ε 33T /ε 0 |

8000 | 6600 | 5700 | 5400 | 5250 | 4000 | 3400 | 3000 | 1900 | 1350 | |

| Coercive electric field |

Ec |

V/mm | 320 | 420 | 470 | 450 | 570 | 670 | 720 | 820 | 870 | 約2000 |

| Curie Temperature |

Tc |

℃ | 125 | 145 | 155 | 154 | 170 | 210 | 230 | 250 | 300 | 320 |

| Dielectric Loss Factor | tanδ | % | 3.8 | 2.4 | 2.2 | 2.6 | 2.3 | 1.8 | 2.1 | 1.5 | 2 | 0.3 |

| Coupling Coefficient |

kp |

% | 68 | 71 | 71 | 71 | 69 | 70 | 70 | 70 | 71 | 61 |

|

k31 |

% | 41 | 43 | 42 | 44 | 41 | 43 | 44 | 43 | 42 | 35 | |

|

k33 |

% | 73 | 75 | 77 | 79 | 77 | 75 | 79 | 78 | 77 | 72 | |

|

kt |

% | 51 | 52 | 51 | 52 | 51 | 51 | 53 | 52 | 51 | 49 | |

| Frequency Constant |

Np |

Hz・m | 1970 | 1910 | 1870 | 1900 | 1987 | 1930 | 1945 | 1957 | 1980 | 2200 |

|

N31 |

Hz・m | 1410 | 1430 | 1430 | 1430 | 1426 | 1420 | 1440 | 1415 | 1480 | 1620 | |

|

N33 |

Hz・m | 1320 | 1310 | 1350 | 1270 | 1342 | 1320 | 1290 | 1333 | 1350 | 1490 | |

|

Nt |

Hz・m | 2070 | 2050 | 2070 | 2020 | 2097 | 2060 | 2080 | 2094 | 2080 | 2020 | |

| Piezoelectric Constant |

d31 |

x10-12m/V |

-440 | -410 | -370 | -375 | -355 | -325 | -300 | -283 | -207 | -133 |

|

d33 |

x10-12m/V |

880 | 820 | 760 | 801 | 745 | 645 | 640 | 573 | 440 | 312 | |

|

g31 |

x10-3m/N |

-6.4 | -7.1 | -7.4 | -7.9 | -7.6 | -9.2 | -10.0 | -10.8 | -12.3 | -11.1 | |

|

g33 |

x10-3m/N |

12.8 | 14.0 | 15.1 | 16.8 | 16.1 | 18.2 | 21.3 | 21.9 | 26.2 | 26.1 | |

| Elastic Constant |

s11E |

x10-12m2/N |

16.2 | 15.7 | 15.5 | 15.5 | 16.1 | 16.1 | 15.5 | 16.3 | 14.5 | 12.0 |

|

s33E |

x10-12m2/N |

20.5 | 20.7 | 19.6 | 22.1 | 20.3 | 20.8 | 21.8 | 20.7 | 19.4 | 15.7 | |

|

c11E |

x1010N/m2 |

13.6 | 13.2 | 13.6 | 14.2 | 14.0 | 13.3 | 15.3 | 13.9 | 15.2 | 14.4 | |

|

c33E |

x1010N/m2 |

12.7 | 12.4 | 12.9 | 12.4 | 12.8 | 12.4 | 12.8 | 12.7 | 13.0 | 12.3 | |

| Poisson's Ratio | σ | 0.28 | 0.24 | 0.27 | 0.24 | 0.30 | 0.26 | 0.30 | 0.30 | 0.30 | 0.30 | |

| Mechanical Quality Factor | Qm | 40 | 50 | 50 | 35 | 45 | 50 | 60 | 56 | 50 | 2500 | |

| Density | ρ |

x103kg/m3 |

7.8 | 7.8 | 7.9 | 7.9 | 7.6 | 7.7 | 7.8 | 7.6 | 7.9 | 7.9 |

| Average Grain Size | D | μm | 5 | 4 | 4 | 2-3 | 2-3 | 5 | 2 | 2 | 1-2 | 2-3 |

| Type | Soft material | Hard material | ||||||||||

Manufacturer:Tayca Corporation Country of origin:Japan

Piezoelectric material: Description of items .

|

Relative permittivity(ε 33T /ε 0 ) |

Indicates the ratio with the electric permittivity of a vacuum and the ability of the insulator to store electric energy in an electrical field. |

|---|---|

| Coupling Coefficient(k) | Efficiency at which electrical energy is converted into mechanical (kinetic) energy |

| Piezoelectric Constant(d) | Indicates the magnitude of the strain (displacement) when voltage is applied |

| Piezoelectric Constant(g) | Indicates the output voltage for the force that is applied |

| Elastic Constant(s) | Magnitude of the strain for the force that is applied |

| Frequency Constant(N) | Product of the length and its primary resonance frequency in the corresponding direction |

| Curie Temperature(Tc) | Critical temperature at which the crystal system changes and loses polarization |

| Dielectric Loss Factor(tanδ) | Electric energy is consumed as thermal energy by the phase angle that occurs when an AC voltage is applied to a dielectric. Dielectric Loss Factor indicates the size that is consumed as thermal energy. |

| Mechanical Quality Factor(Qm) | Indicates the sharpness of the mechanical vibration at resonance frequency |

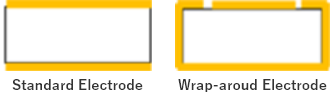

Piezoelectric ceramic electrode options

- Standard Electrode

- Wrap-around Electrode

Electrode Material

- Electrode Ni/Au plating, Ni 0.5 μm, Au 0.5 μm (standard thickness)

- Cr/Au sputtering, Cr 0.05, Au 0.2 μm (standard thickness)

- Fired silver